Advanced driver-assistance systems (ADAS), electric vehicle (EV) powertrains and electronic control units (ECUs) are central to automotive safety and performance. Expert automotive laboratory test technicians ensure the quality, reliability and safety of these systems.

As lab environments modernize, the technician’s role is becoming more strategic. They connect physical testing with digital engineering workflows to deliver faster, more efficient and informed testing outcomes.

How Laboratory Test Technician Roles Are Evolving

Traditionally focused on manual equipment operation and data collection, technicians are now expected to manage complex testing systems and interpret real-time analytics.

Automation has reduced the time spent on repetitive tasks, allowing technicians to focus on specialized tasks such as test planning, equipment calibration and root cause analysis. Digital tools, including sensor-integrated platforms and cloud-based data systems, are also improving traceability and consistency across test environments.

Laboratory testing is also changing in other ways:

- The shift to electronics: The automotive industry is moving to sophisticated electronic architectures, which demand expertise in electronics, software and data analysis.

- Impact of emerging technologies: Advancements in ADAS, autonomous driving and EV technologies require more complex and comprehensive testing protocols to ensure safety and reliability.

- Current industry challenges: The automotive industry faces various challenges, including chip shortages, rapid technological advancements and increasing regulatory pressures. Skilled test technicians are essential for navigating these obstacles and developing new vehicles efficiently.

Critical Functions and Responsibilities

Lab test technicians validate automotive components and systems through controlled, repeatable test procedures. Their work directly supports product reliability, regulatory compliance and time-to-market objectives. Their core responsibilities include:

Electronic Component Testing

Technicians conduct precise tests on complex electronic components, such as microcontrollers, power modules, sensors and application-specific integrated circuits, that meet stringent performance standards. Testing may involve simulated environmental conditions such as temperature extremes, vibration and electromagnetic interference.

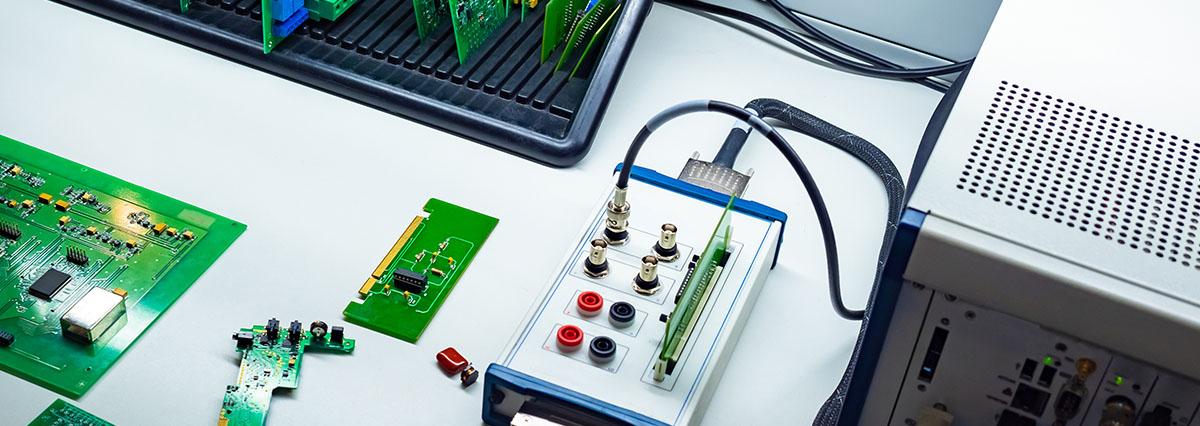

Technicians use oscilloscopes, logic analyzers, signal generators and other diagnostic tools to assess signal integrity and detect latent defects. The goal is to ensure every component performs reliably across its full design envelope.

Automotive ECU Testing

ECU test protocols are a core function of laboratory testing. Technicians follow structured test cases developed by systems and validation engineers to confirm ECU behavior under normal, fault and edge-case conditions. These protocols often include hardware-in-the-loop (HIL) or software-in-the-loop simulations. Test execution requires a working knowledge of communication protocols like CAN, LIN and FlexRay, as well as the use of test automation software and custom test benches.

Implementing and executing test protocols for ECUs supports adherence to customer specifications and industry standards. One example is DO-178C, formally known as Software Considerations in Airborne Systems and Equipment Certification.

Data Collection, Analysis and Documentation

Accurate data collection and thorough documentation are essential for validating test outcomes and supporting cross-functional engineering decisions. Lab test technicians are responsible for logging detailed measurements, test configurations, pass/fail results and environmental conditions in real time. Data analysis uses custom scripts, spreadsheets or software to look for trends, deviations and anomalies.

Technicians format their findings into structured test reports that meet organizational and regulatory documentation standards. These reports are used in design reviews, certification processes and quality audits, making clarity and traceability critical.

Complex Systems Troubleshooting

Lab environments often require technicians to troubleshoot electronic systems with multiple subsystems interacting through embedded software and networked communications. When anomalies occur during testing, technicians isolate faults at the hardware, firmware or integration level.

Troubleshooting may also include working with engineering teams to replicate issues and propose corrective actions. Their hands-on expertise helps reduce development cycles and promotes system-level reliability in the final product.

Equipment Maintenance and Calibration

To maintain test integrity and repeatability, lab test technicians perform regular maintenance and calibrate test equipment, including environmental chambers, digital multimeters, oscilloscopes, signal generators and automated test stations. Calibrations are done in accordance with internal quality standards and external benchmarks, such as ISO/IEC 17025 for testing and calibration laboratories.

Technicians manage calibration schedules, document results and escalate deviations or equipment faults. Reliable equipment ensures consistent test outcomes, minimizes measurement uncertainty and supports quality assurance throughout the product life cycle.

Collaboration With Engineers

Lab technicians work closely with engineers throughout the development process. They provide feedback on test results, assist in root-cause investigations and contribute to design modifications based on empirical data. Regular communication ensures testing aligns with all essential parameters.

Technicians also support engineering during prototype development, providing insights into manufacturability, test coverage and design-for-test considerations. Their collaboration plays a key role in achieving both product performance targets and delivery timelines.

Choosing the Right Automotive Testing Laboratory Staffing Partner

Selecting the right service provider is a strategic decision. Look for a partner with technicians who, in addition to professional qualifications, have:

- Technical certifications: Electronic systems validation technicians should have ASE certifications for electrical and electronic systems, Certified Electronics Technician certification, or other relevant industry certifications.

- Software proficiency: The right provider will have expertise in data acquisition systems such as LabVIEW and MATLAB, diagnostic tools such as CANalyzer and Vehicle Spy, and simulation software like Simulink.

- Soft skills: Look for exceptional attention to detail, strong problem-solving skills, excellent communication skills and the ability to work effectively in a team environment.

- Industry standards: Professional providers will be familiar with industry standards and testing protocols, including ISO 26262, SAE J1939 for CAN Communication and relevant EMC or EMI standards.

Partner With Unitek Technical Services, for Trusted Laboratory Solutions

Lab test technicians are incredibly important in successful automotive development programs, particularly those that involve aerospace and defense-grade standards. As automotive technologies advance, technicians will become even more essential in supporting innovation at every stage.

Unitek Technical Services, is a leading provider of specialized technical support services. We offer expertise in automotive electronic control systems testing. Our laboratory technicians have extensive knowledge of automotive electronics, CAN bus systems, sensor technology, embedded systems, and automotive communication protocols, and more.

Contact us today for all your laboratory staffing and vehicle electronics testing specialist needs. Our team can assist with any personnel requirement, size or scope.