Aerospace manufacturing demands zero-defect quality, yet the gap between engineering specifications and shop-floor execution remains a persistent challenge. Control plans that are too vague create interpretation errors and quality escapes, while plans that are too complex overwhelm operators and slow production.

An effective quality control plan translates Technical Data Package (TDP) requirements into clear, operator-executable inspection criteria while establishing risk-based sampling rationale, measurement protocols and traceability systems.

Creating shop-floor-ready control plans requires identifying Key Characteristics (KCs), establishing Process Failure Mode and Effects Analysis (PFMEA)-based sampling frequencies, enforcing measurement accuracy standards, structuring AS9102-compliant traceability and designing clear material review board (MRB) protocols.

1. Translating Engineering Requirements Into Inspection Criteria

Converting design intent from TDPs into actionable shop-floor instructions requires clarity and precision.

Identify Key Characteristics

Not all dimensions require equal scrutiny. Distinguishing between standard features, KCs and Critical Safety Items (CSIs) enables quality resources to focus on features with the greatest impact on compliance, product quality and manufacturing efficiency.

KCs, as defined by AS9103B, are features whose variation influences fit, performance, service life or manufacturability. CSIs are identified as critical for operational safety and regulatory compliance. CSIs and KCs demand enhanced Statistical Process Control and documentation, while standard features need normal inspection.

Define Objective Criteria

Replace subjective language with quantifiable standards and Special Process parameters that operators can measure or verify. For example:

- Instead of “clean surface,” specify “no visible contamination at 10x magnification.”

- Instead of “workmanlike finish,” specify “surface finish ≤ 32 Ra.”

- Instead of “heat treat okay,” specify “verify oven temp 950°F ±25°F for 4 hours.”

Reference applicable specifications, such as Aerospace Standards (AS) or Military Standards (MIL-STD), in the control plan so operators know the authoritative source for each requirement.

Simplify for the Shop Floor

Avoid technical jargon without definitions, as ambiguity leads to interpretation errors and nonconformances. Control plans must answer four critical questions:

- What to inspect

- When to inspect

- How to measure

- What’s acceptable

Include visual aids, such as photos or diagrams, to support visual inspection criteria and eliminate subjective interpretation.

2. Establishing a Rationale for Sampling Frequencies

Not every part requires 100% inspection. A risk-based approach balances quality assurance with production efficiency, focusing resources on features where variation creates the greatest risk.

Risk-Based Sampling

Use PFMEA to dictate inspection frequency based on feature criticality:

- High-risk features, such as KCs, require 100% inspection

- Medium-risk features require statistical sampling per aerospace standards, such as c=0 Zero Acceptance Number plans

- Low-risk features are cosmetic and non-functional and require reduced frequency sampling

The PFMEA Risk Priority Number quantifies the likelihood and severity of potential failures. Document the rationale for sampling decisions in the control plan so auditors and new team members understand the logic behind inspection frequencies.

Process Capability Impact

Process capability demonstrates manufacturing consistency over time. When the Process Capability Index demonstrates that the process produces parts consistently well within tolerance, organizations can justify reduced inspection frequency. They must demonstrate sustained capability through initial studies before implementing any reduction.

Trigger Points for Escalation

Define clear rules for reverting to 100% inspection when sampling reveals defects. A single nonconforming part requires inspecting the remaining lot 100% per the c=0 rule. Two consecutive failures require stopping the line until the root cause is corrected. Process changes in tooling, material or operator require resetting to 100% inspection until new capability is demonstrated. Document escalation criteria in the control plan to eliminate decision ambiguity.

3. Validating Measurement Systems and Calibration Standards

Measurement accuracy is fundamental to quality control. Using incorrect or uncalibrated tools invalidates inspection results, leading to quality escapes.

Select the Correct Gage

The 10:1 Rule states that gage accuracy should be 10 times better than the feature tolerance being measured. For a ±0.010-inch tolerance, gage resolution must be 0.002 inches or finer. Inadequate gage resolution can’t detect variation within the tolerance band.

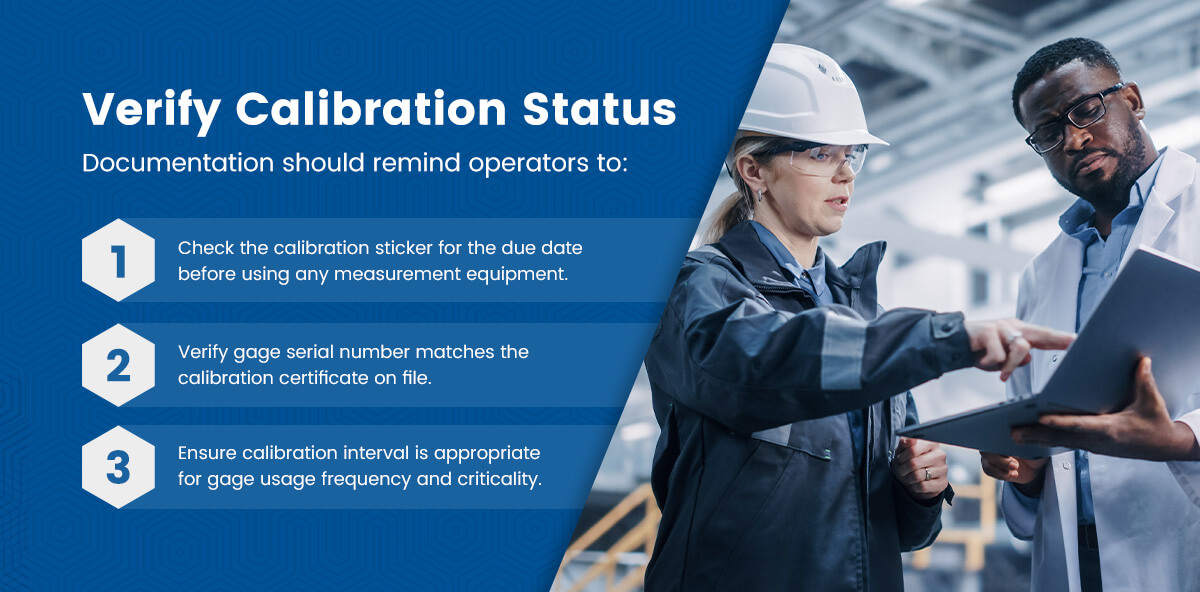

Verify Calibration Status

Mandate calibration verification before inspection begins. Documentation should remind operators to:

- Check the calibration sticker for the due date before using any measurement equipment.

- Verify gage serial number matches the calibration certificate on file.

- Ensure calibration interval is appropriate for gage usage frequency and criticality.

A compliant measurement from an uncalibrated tool results in quality escapes.

Gage Repeatability and Reproducibility (Gage R&R)

Gage R&R studies ensure different operators achieve consistent results. Acceptable gage R&R results show measurement system variation at or below 10% of tolerance.

Perform gage R&R before production begins and whenever measurement concerns arise, such as inconsistent results between shifts or operators. Document required measurement equipment in the control plan by feature, so operators select the correct tool every time.

4. Maintaining Traceability and Record Retention

Aerospace traceability allows for quick isolation of problems if material or process issues are found.

Document Actuals vs. Pass/Fail

For critical aerospace components, recording actual variable data is often required rather than simple pass/fail attribute inspection. Actual measurements enable trend analysis and the validation of AS9102 First Article Inspection. Variable data reveals process centering and capability, while attribute data only confirms conformance at a single point in time.

Maintain Lot and Configuration Integrity

Link inspections to specific material lots and engineering revisions by:

- Documenting raw material heat or lot numbers for traceability to source material certifications

- Recording special process batch numbers for heat treatment, plating or coating operations

- Verifying the part is being built to the latest drawing revision to prevent obsolete configuration escapes

Lot traceability allows precise containment if raw material issues are discovered after production.

Audit-Ready Archives

Organize records to meet extensive retention periods of 7 to 40 years as per AS9100D Record Retention Requirements. Digital systems with backup and retrieval capabilities are preferred over paper records due to space constraints and search functionality. Records must include part number, revision level, serial or lot number, inspection date, inspector identification, actual measurements, and accept/reject disposition.

5. Designing Clear Reaction Plans for Nonconformances

What organizations do after they find a defect determines whether the problem gets contained and corrected or escalates into a systemic quality issue.

The “Stop-Call-Wait” Protocol

Define immediate operator action upon finding a defect:

- Stop: Cease production immediately and do not produce additional parts.

- Call: Notify supervisor or quality engineer, and do not attempt unauthorized rework or repairs.

- Wait: Quarantine suspect parts in the designated hold area, awaiting disposition decision from authorized personnel.

Document the protocol prominently in the control plan and at workstations where operators can reference it immediately.

Containment Procedures

Quarantine suspect parts immediately using designated hold areas with red tags or other clear visual indicators. Check recent production, working backward to bracket the defect and determine when the problem started. Inspect similar parts from the same lot, operator or time period to assess the full scope of the issue. Containment prevents nonconforming material from advancing to the next operation or shipping to the customer.

Material Review Board and Corrective Action

Link nonconformance to the formal MRB process for disposition decisions, including scrap, rework or use-as-is with engineering concession. Only authorized MRB personnel can approve non-standard dispositions.

Initiate a corrective action request to investigate root cause. Track corrective action effectiveness through follow-up audits to verify the problem has been eliminated.

Ensure an Effective Quality Control Plan With Unitek Technical Services

A robust control plan bridges the gap between engineering intent and manufacturing reality. Proper planning helps prevent quality escapes, supports efforts to reduce rework costs and facilitates regulatory compliance, but executing effective control plans requires the right expertise and scalable resources.

Unitek Technical Services partners with aerospace manufacturers to strengthen the effectiveness of control plans through quality engineering support and process verification services.

With over 45 years of experience helping customers deliver products the world can trust, our specialists provide scalable inspection resources that act as an extension of your team. Our Launchpad portal delivers 24/7 visibility into inspection results, while our backing by Kiwa ensures global resources with local expertise.

Contact us today to strengthen your quality control planning and inspection capabilities.