Many industries, including aerospace and defense manufacturing, face strict standards. Every fastener, weld and circuit must meet precise specifications, as a single flaw can delay production, raise costs and jeopardize mission success. Programs run on tight schedules and even tighter budgets, leaving little room for rework.

The purpose of in-process inspection is to address these pressures by verifying quality at each step and allowing teams to detect nonconformances before they spread. This approach protects schedules, reduces scrap and improves compliance with stringent regulatory requirements.

Why Are In-Process Checks Important?

In-process inspection systematically evaluates parts, assemblies and processes during production rather than after completion. It proactively verifies that each step meets specifications during manufacturing or assembly to reduce the chance of defects.

In aerospace and defense manufacturing, in-process inspection is not optional — but embedded in the production life cycle. Standards such as AS9100, ISO 9001 and NADCAP require manufacturers to document and demonstrate process control.

Compliance with these standards ensures products perform reliably under extreme conditions. In-process inspection is important in industries with precise tolerances, traceability and risk mitigation demands. Only detecting nonconformances at final inspection can lead to expensive rework or scrapped components.

This practice also supports customer confidence. Government agencies and prime contractors expect documented evidence of process control. In-process inspection provides proof, showing suppliers meet both technical and regulatory requirements before delivery.

What Are the Benefits of the Inspection Process?

By integrating checks during production, organizations enjoy measurable advantages that improve their overall performance. These benefits extend beyond the factory floor and into the supply chain and customer relationships. In addition to early defect detection and regulatory compliance, core benefits include:

- Better traceability: In-process inspection captures real-time data at each step, ensuring components and processes can be tracked from start to finish.

- Cost control: This proactive testing prevents expensive rework and warranty claims by resolving problems during manufacturing rather than after.

- Boosts customer confidence: Government agencies and other stakeholders see quality assurance and strengthened supplier credibility, which increases future contract potential.

- Continuous improvement: In-process testing provides actionable data to refine processes, reduce variation, improve sourcing operations and increase long-term reliability.

Return on Investment

In-process inspection produces a positive return on investment (ROI) by reducing hidden costs. Uncaught defects increase labor, materials and schedule errors. They can also damage a supplier’s reputation and lead to lost contracts. Documented process control prevents these losses. Organizations implementing robust inspection protocols typically see lower warranty claims, fewer production schedule delays and higher on-time delivery rates. Over time, these savings outweigh the initial cost of implementing inspection systems.

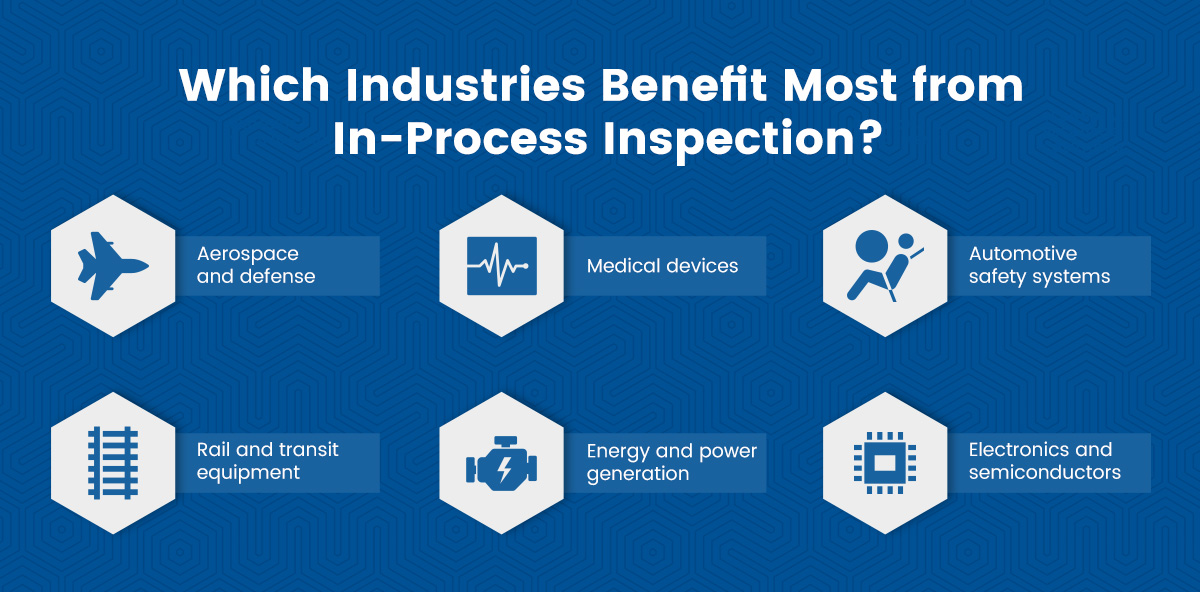

Which Industries Benefit Most from In-Process Inspection?

Aerospace and defense rely heavily on in-process inspections because of their strict quality requirements, but other sectors also benefit from them. Any operation where nonconformance affects lives or significant capital can benefit from this proactive approach, for example:

- Medical devices: Surgical implants and diagnostic equipment require strict process validation to meet FDA and ISO 13485 requirements.

- Automotive safety systems: Airbags, braking systems and electric vehicle batteries demand real-time quality checks to prevent accidents and recalls.

- Rail and transit equipment: High-speed rail components and signaling systems rely on traceable manufacturing processes to ensure passenger safety.

- Energy and power generation: Turbines, offshore platforms, and nuclear components use in-process inspection to prevent catastrophic failures.

- Electronics and semiconductors: Defense-grade microchips and avionics boards undergo detailed process verification to ensure reliability in extreme environments.

It is especially important in multi-stage assembly lines, where products need customization or frequent changeovers and for suppliers who have new vendors or unproven production capabilities.

How In-Process Inspection Supports Supply Chain Resilience

By embedding inspection into production, suppliers reduce the risk of issues during final assembly or acceptance testing. This practice helps prime contractors and government agencies plan with greater confidence because they get parts that conform to specifications the first time. It also creates a data trail that enables faster root-cause analysis if issues arise later.

Resilient supply chains rely on transparency and rapid response. Real-time inspection data lets managers identify emerging trends, coordinate corrective actions and prevent disruptions from spreading. Suppliers who can demonstrate process control often become preferred partners, earning more stable, long-term contracts.

Digital Transformation: Real-Time Inspection and Data Management

Digital tools and secure data portals fundamentally change how inspection is managed in production environments and create transparency for all stakeholders. Secure portals provide controlled, role-based access to process metrics and inspection results with live dashboards showing part status, defect trends and yield rates. This lets teams respond to deviations immediately.

For example, if a torque reading drifts outside tolerance, the system alerts operators, pauses downstream operations and requires corrective action. It accelerates root-cause analyses and reduces reliance on guesswork.

More benefits of digital in-process inspections include:

- Data-enabled decision-making: Analytics highlight trends, predict failures or identify process drift.

- Reduced administrative burden: Automated capture replaces manual entry and report consolidation.

- Secure collaboration: Portals allow controlled, sensitive quality data sharing across tiers and with clients.

- Scalable architecture: Cloud or edge deployments can grow with production volume and inspection complexity.

What an In-Process Inspection Looks Like

The details of an in-process inspection vary by product and sector, but most inspections follow a structured routine in which quality engineers identify critical stages in the manufacturing process, such as machining, welding, assembly or testing. With clear specifications, drawings and checklists tied to standards like AS9100 or NADCAP, engineers verify dimensions, tolerances and other critical parameters.

Data is entered into a digital quality management system or secure portal, often with timestamps or operator IDs for traceability. If a measurement fails, the part or process stops. Corrective actions are documented, and engineering teams may review the process before work resumes.

Enhance Your Supply Chain With Unitek

Quality assurance is critical in high-reliability industries. Program deadlines are tied to launch schedules, defense readiness or patient safety. One weak link can compromise the entire operation. In-process inspection minimizes that risk by turning quality into a shared responsibility across the supply chain.

At Unitek Technical Services a Kiwa Company, we have over 45 years of experience in testing, inspection and certification for various industries. We understand that in modern-day supply chain management, a just-in-time (JIT) inventory is crucial, and our team of knowledgeable professionals ensures timeliness for all in-process inspections. From product verification to audits and surveys, and supply chain management, we provide services to a variety of corporate sectors.

Complete our contact form today for more information on streamlining your production processes.